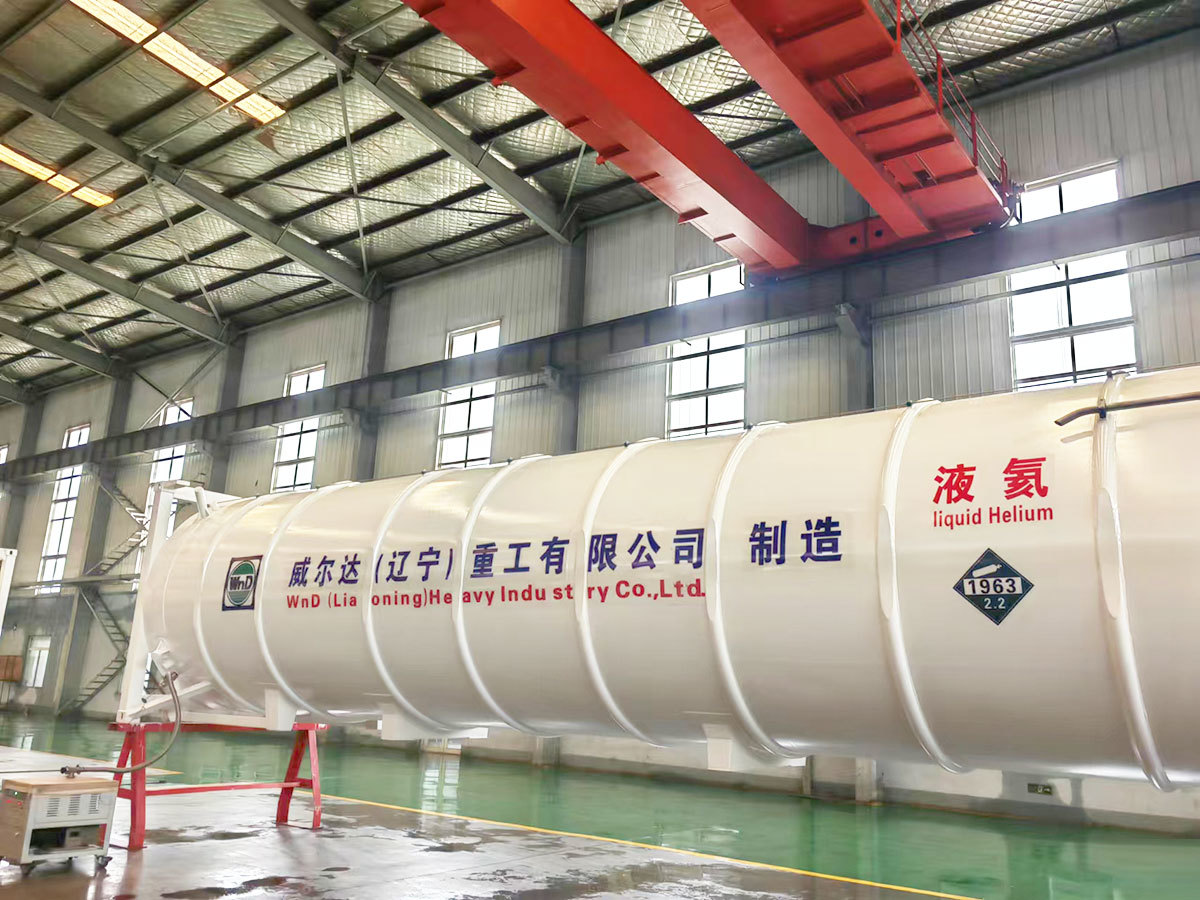

40 ft (43.5m ³) liquid helium container

Classification:

1.0 technical characteristics 1.1 Design & Testing Tank Case: Comply with Specification: RID/ADR, IMDG and ASME Volume 8 Division 1, T75 UN Transportable Tank Case Frames: per specification: ISO1496/3 ML2 beam frame design Corner Casting: ISO 1161/Size and Type Code: 42KW

1.0 technical characteristics

1.1 Design & Testing

Tank Case: Comply with Specification: RID/ADR, IMDG and ASME Volume 8 Division 1, T75 UN Transportable Tank Case

Frames: per specification: ISO1496/3 ML2 beam frame design

Corner Casting: ISO 1161/Size and Type Code: 42KW

1.2 frame size and mass

Maximum allowable total mass: 36 000 kg

Weight (± 3% tolerance):17344kg

Length: 12192mm 40 ft

Width: 2 438 mm 8 ft

Height: 2 591 mm 8 ft 6 in

1.3 tank size

Nominal volume (± 1% tolerance):41067 L

Inner tank

Inner diameter: 2200 mm

Distance from tangent to tangent: 10070 mm

Corrosion allowance: 0 mm

Head-approximately 2:1 oval

Liquid nitrogen screen tank

Nominal volume (± 1% tolerance):2100 L

Inner diameter: 2330 mm

Corrosion allowance: 0 mm

Head-approximately 2:1 oval

Outer tank

Inner diameter: 2400 mm

Tangent to tangent distance: 11380 mm

Corrosion allowance: 0 mm

Head-Oval

1.4 pressure & temperature rating

Inner tank: 6.3Bar

Maximum allowable working pressure: 6.3Bar

Design temperature range: 4.2k

Liquid nitrogen screen tank: 0.7Bar

Maximum allowable working pressure: 0.3 Bar

Design temperature range: 77K

Outer tank

Internal design pressure:-1,0 Bar

External design pressure:/

Design temperature range:-40 to 50 ℃

1.5 performance

BS EN 12213-1999 Clause 3.3, Under Standard Conditions: Method of Evaluation of Thermal Insulation

LHe hold time:45 days

1.6 insulation material

Isolation Type: Super insulation Super Insulation

Vacuum layer at room temperature: 2.0x 10-4mbar

Vacuum layer cold: 2.0x 10-6mbar

1.7 manufacturing materials

Frame: Q355GNH GB/T 4171-2008

Outer cylinder: Q345R

Inner tank: SA 240 316L stainless steel

Liquid nitrogen cold screen: SA 240 304 stainless steel

Insulation screen: 5083-O

Anti-wave plate: SA 240 316L stainless steel

1.8 nondestructive testing

| Type | Project | Stage |

| visual inspection | 100% of all welds | Before & after hydrostatic test |

| Ray | All longitudinal and circumferential butt welds | Before hydrostatic test |

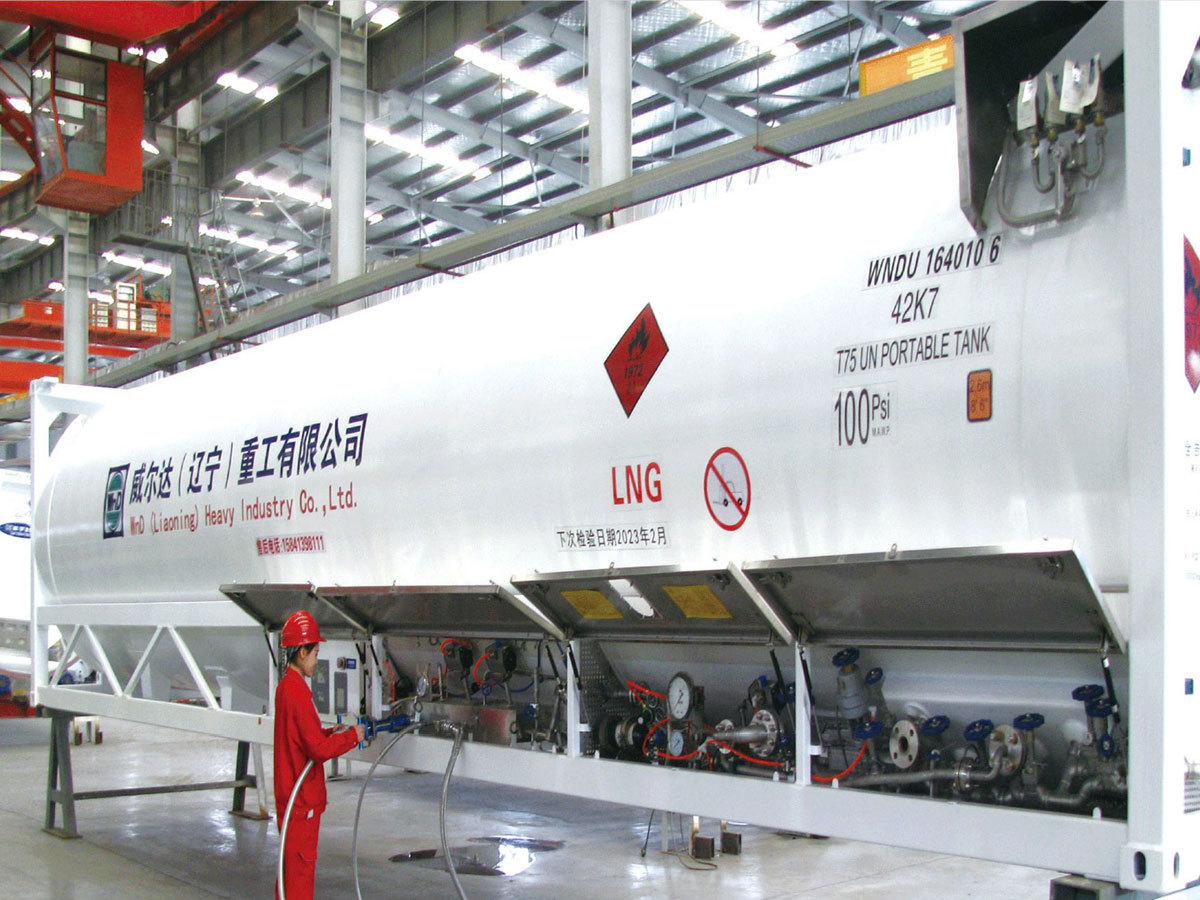

2.0 tank box accessories

• Valve type: stainless steel low temperature long handle valve, high vacuum low temperature long handle valve globe valve

• Liquid helium pipeline using 316L stainless steel Sch10S

• Liquid nitrogen pipe 304 stainless steel Sch10S

2.1 liquid helium bottom fill/liquid line

• Valve supplier: domestic

• Pipe size: 50 NB (2 ")

• 末端连接:ANSI 150# 50NB Flange Blind Flange

• Gasket: PTFE Teflon

2.2 gas phase pipeline

• Valve supplier: domestic

• Pipe diameter: 50 NB (2 ")

• 末端连接:ANSI 150# 40NB Flange Blind Flange

2.3 discharge line

2.4 liquid nitrogen dewar outlet line

• Valve supplier: domestic

• Pipe size: 3/4"

• End connection: KF flange blind flange

Installation of 2.5 safety valve burst disc

• Liquid helium valve supplier: domestic

• Liquid Helium Safety Valve Specification: Pressure Setting 91psi

Set pressure 91psi

• Liquid helium bursting disc specification: pressure setting 106psi

Set pressure 106psi

• Valve supplier: domestic

Quantity: 1 x ¾ "x 4 three-way divertor switching valve (safety valve and rupture disc)

• Liquid nitrogen valve supplier: domestic

• Liquid Helium Safety Valve Specification: Pressure Setting 10psi

Set pressure 10psi

• Quantity: ¾ "x 1

• Liquid helium bursting disc specification: pressure setting 17.4psi

Set pressure 17.4psi

• Valve supplier: domestic

• Quantity: ¾ "x1

2.6 level gauge

• Vendor: Wika

• Number of: 2

• Specifications: Millimeter scale with conversion table on the tank

2.7 pressure gauge

• Vendor: Wika

Number of: 3

• Specifications:

2 × indicates the gas phase pressure of helium in the tank and 1 × indicates the gas phase pressure of nitrogen in the tank.

2.8 ventilation standpipe

Two standpipes, all drain valves, bursting discs and safety valves are discharged to the ventilation standpipe above the tank. Separate discharge of helium and nitrogen

2.9 File Loader

1-A waterproof PVC file loader is installed on the frame.

2.10 stamp

One per tank as per specification. The user logo.

2.11 Data Board

One 304 stainless steel data plate per tank per specification.

2.12 valve box

304 stainless steel valve protection box, complete with door.

2.13 tank bracket

1-set of stainless steel cylinder mounting bracket. The mounting bracket is fixed in the valve box.

2.14 sensor

Sleeve stainless steel barrel mounting bracket. The mounting bracket is fixed in the valve box.

3.0 complete

3.1 inside

Internal barrel surface

Weld

3.2 external

External surface: sand inspection before paint inspection SA2 ½

Weld

3.3 Accessories

All fittings, including valves and pipes, need to be deoiled and stored in a clean sealed plastic bag until installed on the tank. Clean standards for post-storage oxygen are met.

3.4 cleaning

After the assembly is completed, the internal surface of the inner tank needs to be deoiled, salt washed and passivated. A cleaning certificate is required.

3.5 leak test and nitrogen purge

The inner and outer tanks were tested for helium mass spectrometry leak detection. The tank is purged with nitrogen. Use dry nitrogen (O2<1% residual oxygen, 1.0 bar pressure, nitrogen dew point -20 ℃).

3.6 painting

Carbon steel frame assembly sandblasted SA2 ½, painted as follows:

第一层 Interzinc 42 50 micron min DFT

中间层 Intergard 475HS 60 micron min DFT

最后一层 Interthane 990 50 micron min DFT

TOTAL 160 micron min DFT

Color: Hempel 10000 bright white

Sand inspection SA2 ½ for carbon poem outer tank, paint inspection shall be as follows:

第一层 Interzinc 42 50 micron min DFT

中间层 Intergard 475HS 60 micron min DFT

最后一层 Interthane 990 50 micron min DFT

TOTAL 160 micron min DFT

Color: Hempel 10000 bright white

3.7 tests and components

The tank design follows the reviewed drawings.

Each production unit has been tested and non-destructive as required by ASME Volume VIII and the manufacturer itself. Each unit is inspected by an authority BV.

Each corner post of the tank bears a weight of 86400kg for the stacking test, and there are 9 highly stacked (8 x 24000kg).

The UN portable tank meets the performance specifications required by the following international agencies:

IMDG - T75

RID/ADR – T75

Additional Approvals:

TIR/Customs

CSC

S & N (36000kg with a P decal)

TC Impact Approved

US DOT

3.8 file

The following documents are required

• Operation Manual

• Cleaning certificate (placed in file loader)

• Initial inspection certificate for each tank

• Nameplate details

• Data books

4.0 Products

UN1963 Helium, refrigerated liquid. Helium, refrigerant

5.0 overall

• 316L/304 inner tube stainless steel 316L/304

• Paint can be maintained for 8 years

Related Products

Online consultation

Contact us today for free expert advice!

Contact Us

Address: No.51, Shendong 4th Road, Fushun Economic Development Zone, Liaoning

Service Hotline: 86-24-53826136

Mr. Zhu: 86-18041329999

E-mail:wndzhonggong@163.com